ACHIEVING SUSTAINABILITY GOALS TOGETHER

Next-generation manufacturing for the next generation

Like our manufacturing ecosystems, we want to protect the wider ecosystem in which we all live in. So we build efficient machines with unstoppable OEE, helping to optimise your business’s performance and in turn, reduce the damaging effects on the environment.

Our green innovations can help your business boost its green credentials and have a better impact on the planet.

Reduce single-use plastics with sustainable materials

We’re committed to reducing manufacturers’ reliance on single-use plastic, meaning you don’t have to choose between profit and planet. So when a leading electronics brand wanted to remove ‘pointless plastics’ from their batteries, we worked with them to develop an innovative machine to pack in paper. This made the process both greener and faster.

Other plastic reducing projects include packing P&G’s toothbrush in a plastic-free carton; substituting Nestle’s plastic sticks for paper; and working with our partner, A-Top, to use thinner plastics that retain the shelf life of food.

Lengthen machine lifespans with whole life service

With industry-leading 95% OEE, our whole life service optimises your business performance and reduces excess energy usage as a result of poor machine maintenance.

Reduce transportation footprint with remote assistance and smaller carton sizes

Our digital innovations and remote monitoring software strengthen your green credentials by eliminating unnecessary travel.

And to take even more vehicles off the road, we package your products using less material. So when the supermarket chain Lidl asked us to carefully pack and stack their laundry tablets, our side-loader cartoner got to work compressing the product before being packed. The result? We saved Lidl space to transport more products at once.

And naturally, we practice what we preach, actively monitoring our air miles, road miles, waste, water and energy usage, and taking steps to reduce them.

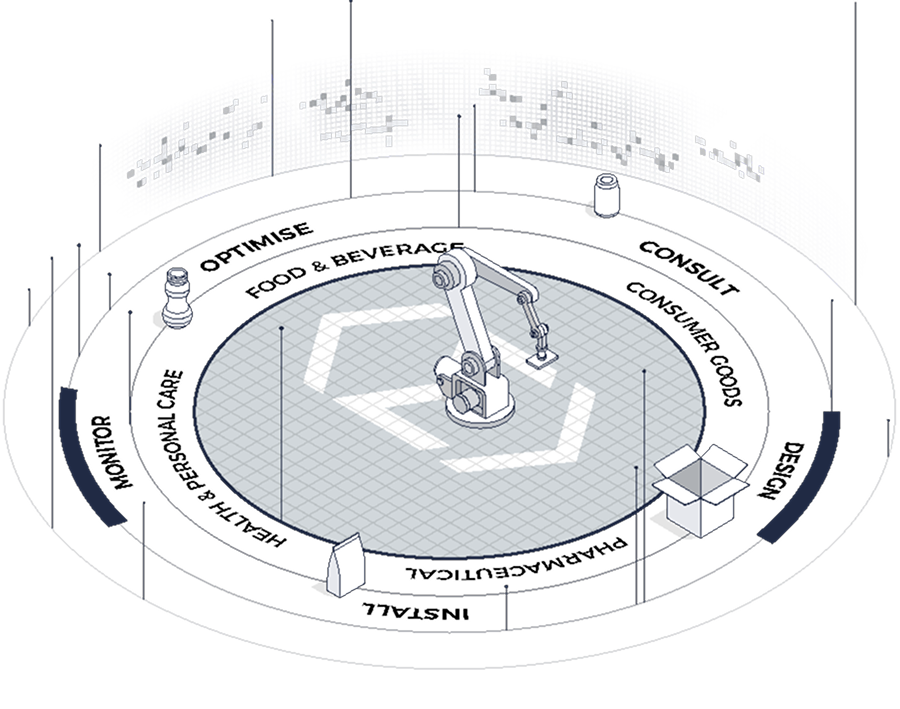

THE AUTOMATION PROCESS

How We Work

We don’t start with assumptions, but with questions. We’ll then work together to help you harness technology, so you can optimise the complex web of moving parts that is your manufacturing line. From your initial consultation to lifetime service, our 5-step approach ensures we find you the best solutions for your current and future needs.