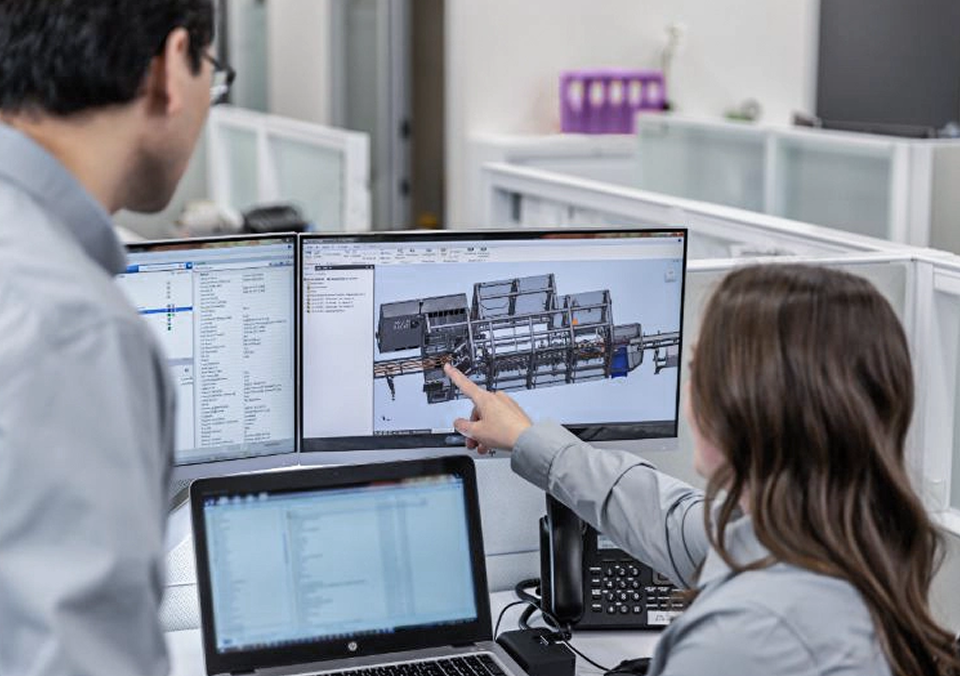

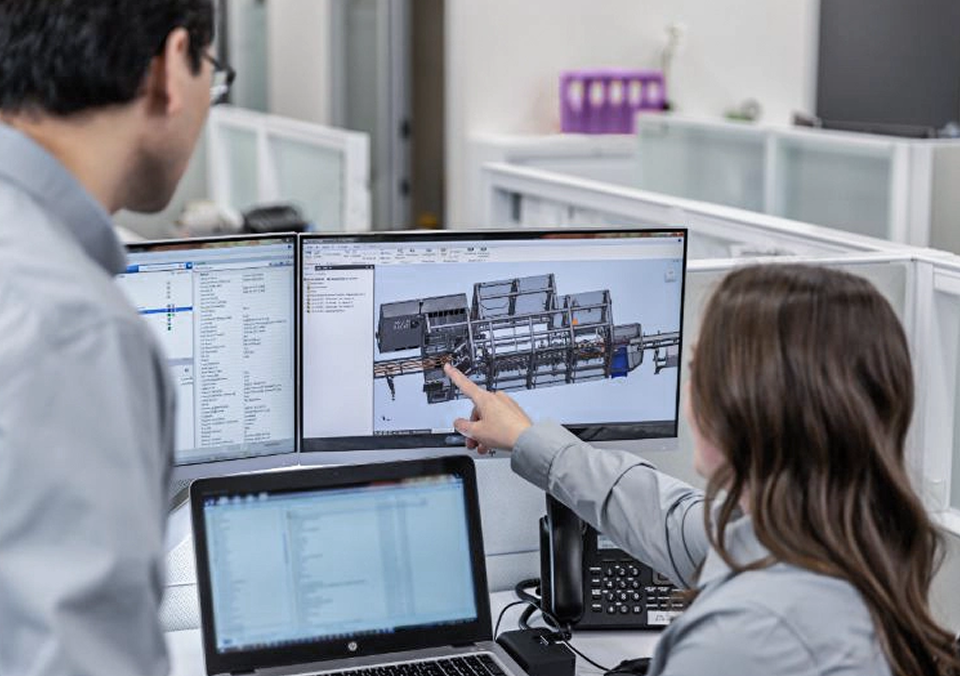

Predictable Support. Proven Performance.

At Mpac, we understand that reliable performance is critical to your success. Our Service Agreements provide proactive, customized support plans that ensure your equipment continues to operate at peak performance – with reduced risk, lower costs and greater piece of mind.

Why chose an Mpac Service Agreement?

- Planned Maintenance

- Priority Support

- Cost Control

- Extended Equipment Life

- Improved OEE

Reduce unplanned downtime with regularly scheduled service visits and performance checks.

Priority scheduling for emergency support

Predictable, budgeted service costs with no surprises

Maintain your assets through expert care and timely part replacements

Enhance machine reliability, speed and quality with ongoing performance optimization.

What's Included?

Every service agreement is tailored to your equipment, usage profile and operational targets and may include:

Scheduled preventative maintenance

Discounted or inclusive spare parts

Emergency Support

Remote Diagnostics and Support

Software Updates and Health Checks

Machine Performance Audits and Optimization

Operator Refresher Training

Technical Support Resources

Flexible Plans that fit your business

- Essential Care

- Performance Care

- Total Care

- Custom Care

routine servicing and system health checks

includes enhanced monitoring, faster response times and priority spares

comprehensive, all-inclusive support with maximum uptime assurance

built around your site’s unique needs, production volume and goals

PROACTIVE, NOT REACTIVE.

Our approach is built around preventative maintenance & continuous improvement, helping you move from reactive fixes to proactive performance management.

With Mpac as your long-term partner, you benefit from:

- Deep technical expertise from the original equipment manufacturer (OEM)

- Access to the latest upgrades and engineering insights

- Clear service history and compliance records

- Greater operational confidence for your team and business