Food & Beverage

Reliable. Scalable. Hygienic. Engineered for Performance.

At Mpac, we deliver intelligent packaging automation systems for some of the world’s most respected food and beverage brands. From raw food handling to high-speed cartoning and end-of-line palletising, our solutions are engineered to meet the demanding pace, hygiene standards and product variety of today’s global food markets.

In food & beverage production, every second and every package counts. Whether you’re packaging ready-to-eat meals, snacks, pizza or canned beverages, Mpac is here to help.

Frozen

Keep your lines flowing and food frozen with our lightning-fast, frozen food cartoners.

Beverages

Our world-class end load cartoners are engineered to meet the needs of canned beverage connoisseurs.

Ready Meals & Prepared Foods

Our flexible cartoners effortlessly handle prepared foods of all shapes and sizes at high speeds.

Snacks & Confectionary Baked Products

Produce up to 400 flow-wraps per minute on our standard cookie and biscuit solution.

Learn More

Food & Beverage Applications

We will help you develop and build primary, secondary and end-of-line packaging machinery for a range of applications and to the most hygienic standards.

Our offering includes the handling, filling, and packaging of:

- Pizza

- Biscuits

- Liquids

- Cereal

- Fresh produce

- Frozen foods

- Powders

- Infusions

- Confectionary / snacks

Packaging Capabilities

Our packaging capabilities include:

- Bag in-box presentations

- Stick packs

- Sachets

- Doy packs

- Bars

- Flow packed items

- Chain packs

- Pouches

- Bags

- Bottles

Solutions for

every stage

We have years of experience in making precision filling and dosing machines across a wide range of markets. Whether you require new dispensing technology or are looking to incorporate fresh methods into your existing application, we have the perfect machine for you.

Standard options and additional accessories available include

- Additional titanium spools and disk holders

- Data transfer configuration

- Customisable report layout

- A4 printer

- Active powder extractor

- Air filtration unit

- Mettler Toledo care pack

- On-site Mettler Toledo calibration

- Validation documentation pack

- Shipping/storage case

They are very turnkey in their approach, and no other supplier can meet the deadlines they can. They have increased our capacity, they are reliable, we have next to no downtime now, it’s a great result.

Extremely robust, high quality, high precision.

They’re proud of what they do, and they want to deliver a good service.

They think in multiple dimensions – technically, commercially and innovatively.

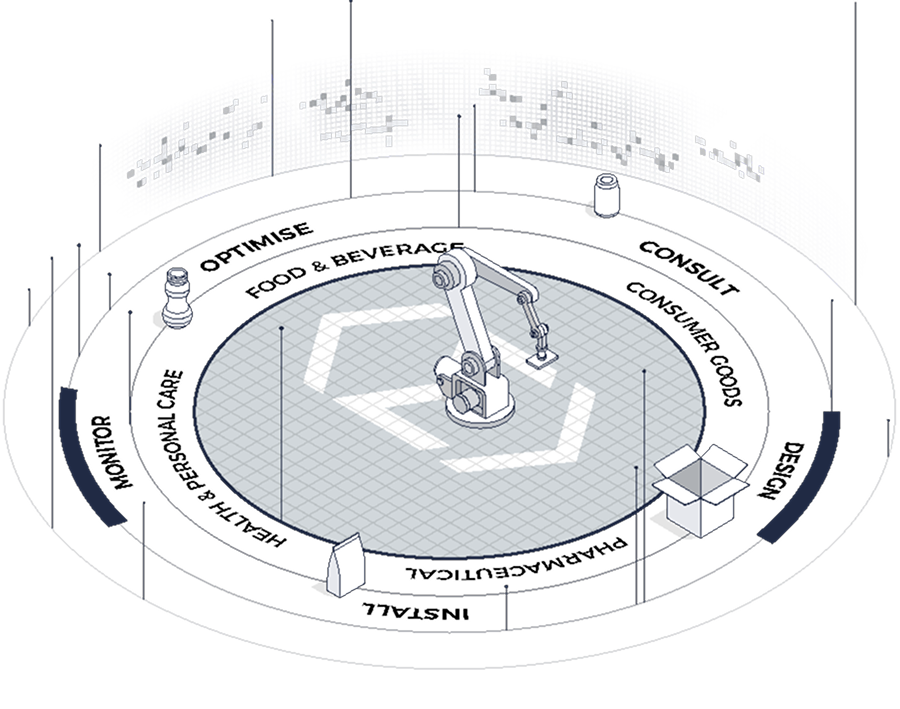

THE AUTOMATION PROCESS

How We Work

We don’t start with assumptions, but with questions. We’ll then work together to help you harness technology, so you can optimise the complex web of moving parts that is your manufacturing line. From your initial consultation to lifetime service, our 5-step approach ensures we find you the best solutions for your current and future needs.